القدرات الواعدة للطباعة ثلاثية الأبعاد

A residential house that is a shape of rotor with contemporary style with wooden flooring, furnished with appliances from Samsung, constructed within 24 hours. Imagine making an own range of jewelry, trinkets or tiny add-ons for daily lives. Can we craft sculptures or showpieces smaller than human hair? A custom prosthetic device such as a hearing aid or artificial human limbs and manufacture them at very affordable prices, which benefits the healthcare industry? A 400 square metre two- story villa with walls of thickness 250 mm, capable of withstanding a level eight earthquake on the Richter scale was built is 45 days.

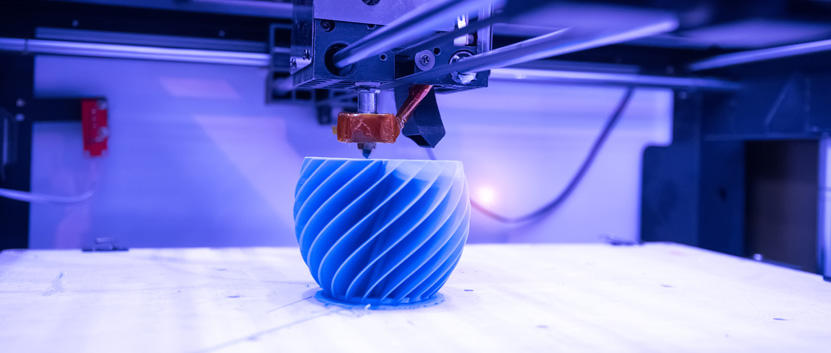

Well, if you are thinking these structures created by employing huge workforce, then you are wrong. These are the wonders created by 3D printing.

What is 3D printing?

3D printing is a method of creating a three dimensional object from a digital file. It is a part of additive manufacturing (AM), where the materials are layered several times until the desired object is created. It starts with creation of blueprint of the desired object, using various 3D modelling software like Blenders or also on websites like Shapeways, Thingiverse that has objects created by other users. The finished design is sent to a 3D printer. The 3D printer reads the file blueprint to lay down into thin layers of material to create the desired 3D object. The materials used in creating the 3D product can vary from plastic to metals to ceramics.

Top 5 Advantages of 3D printing:

- Ease of Customization: when there is mass production, all the parts in the assembly line uses same mold and shape, making it difficult to be exclusive. 3D printing allows us to customize, personalize the product by tweaking the prototype thus fitting to one’s needs. For instance, people can make their own jewelry or fashion or print your own wardrobe.

- Time efficient: with the fast-paced life, we require everything quick and so 3D printing can make a huge difference. With 3D print a concept can transform to reality in a day, shrinks the developmental process from months to days. For example, the time to build houses has shrunken from years to months or days with 3D printing technology.

- Reduce costs: manufacturers can produce products on demand rather than in large runs, improving inventory management and reducing warehouse space. The labour costs are significantly low, as the whole process is automated and demands only an operator to start the machine. In medical field, prosthetic hands can be created in few hundred dollars making it accessible to patients.

- Risk reduction: The manufacturer would always want to test the product design before producing it in large numbers or before investing in an expensive molding tool. Using 3D printing the products can be printed far cheaper than redesign or alter the existing mold.

- Sustainability: 3D printing has multipurpose characteristics, less wastage and cost saving. The materials used in the process are eco-friendly. 3D models transmitted electronically, so they can be printed whenever needed. Compared to the traditional on-site construction Winsun’s (leading 3D construction printer) process save about 80% on construction costs, 60% on labour costs and 60% on waste.

How did 3D printing – initially take off?

3D printing is not as new as you think; it has existed since 1980s. Charles Hull, who invented ‘Stereolithography’ in 1986, created the first 3D printer. He also founded one of the world’s leading 3D printing company ‘3D Systems’.

Since mid-1980s , many new 3D printing technologies have been developed and a variety of new firms entered the marketplace. The basic technology is not new. Until then the cost of 3D printers were expensive ($ 10,000) and huge in size, thus was used by large companies

Over the next decade, the patents for several types of 3D printing technologies expired and increased the levels of innovation. In 2002, scientists from Wake Forest Institute of Regenerative Medicine developed the first 3D printed working kidney, which gained wide media visibility of this technology.

RepRap project, an open source initiative launched with a vision to build a self-replicating 3D printer in 2005. This project opened doors to many advances in the technology. The next few years saw innovations in the industry like DIY kits, bio-printing, customization in vast manufacturing and 3D printing movement started to gain visibility. As a result, the prices of 3D printer dropped from $ 10000 to $ 2000 or less and size shrunk from refrigerator to microwave.

In 2013, President Barack Obama mentioned 3D printing as a major issue for the future in his State of the Union speech, which finished to make “3D printing” an absolute buzzword. The technology revolutionized the industrial sector with its capabilities and wide range applications. More and more small and large companies are invading the technology due to its low prototyping cost.

3D printing has not achieved the heights, and shows immense potential in reshaping the consumer industry.

3D printing in the GCC

3D printing technology is gaining momentum in construction industry as the cost and time are reduced in comparison to the traditional methods.

In 2016, His Highness Sheikh Mohammed bin Rashid Al Maktoum, Vice President and Prime Minister of UAE and Ruler of Dubai, has launched the ‘Dubai 3D Printing Strategy’, a unique global initiative that aims to exploit technology for the service of humanity and promote the status of the UAE and Dubai as a leading hub of 3D printing technology by the year 2030. The strategy aims of 3D printing 25% of Dubai’s buildings by 2030 (Dubai Future Foundation).

According to recent blog by Marmore on Dubai’s 3D printing house crisis, this technology will ease the major challenges faced by the construction industry (labour and cost). Due to the advantages of this technology on time, cost and labour, 3D technology has paved way as a solution to number of problems in housing sector in GCC.

‘Office of the Future’ is the first 3D printed office in the world was unveiled in Dubai within few months of the launch of 3D strategy. It took only 17 days to complete this structure.

3DPME (Threedp), founded by Abdullah Alhussainan in Kuwait in late 2014, provides 3D printing services to companies, sells 3D printers and provides training on the technology. Recently Alhussainan launched an app called INDX, which is a directory to find the makers and designers in 3D printing in Kuwait. The app sponsored by Ministry of Youth Affairs. 3D printing is a one of the promising technology with its huge benefits in comparison to the traditional manufacturing. The adoption of the technology will inject growth in almost all sectors of industries. It has huge potential in creation of job force by introducing new professions like product designers, printer operators or related to production of 3D printers in the market.